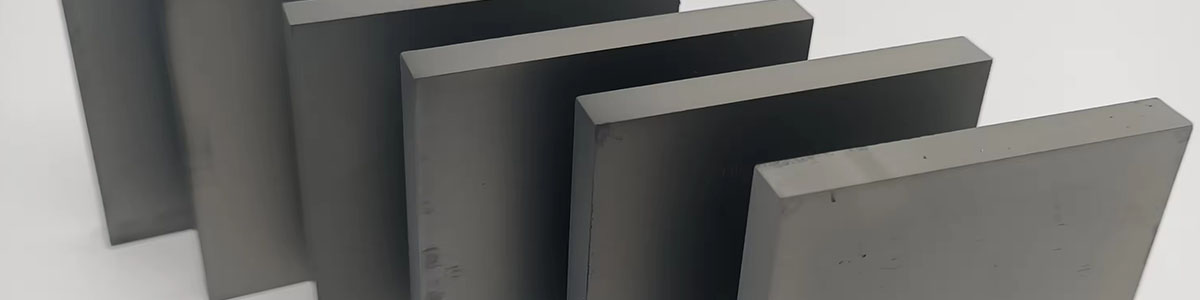

Synthesized silicon carbide powder has been mass-produced since 1893, and was initially used as an abrasive. With the development of new material technology and the increasing social demand, silicon carbide has shown unparalleled application value in many fields.

1.Overview of Silicon Carbide Ceramics

Currently, there are three basic methods for preparing silicon carbide powder: solid phase method, liquid phase method and gas phase method.

After synthesis, silicon carbide mainly has two crystal types: low-temperature stable cubic β-sic and high-temperature stable hexagonal α-sic. Among them, α-sic (green silicon carbide and black silicon carbide) is the main raw material for preparing silicon carbide ceramics.

Silicon carbide ceramics are advanced ceramic materials made of silicon carbide via hot pressing, pressureless sintering, and hot isostatic pressing. They are very hard ceramics and are widely used in automobiles, mechanical chemicals, environmental protection, aerospace technology, information electronics, energy, and other fields.

2.Main Properties of Silicon Carbide Ceramics

Silicon carbide ceramic materials have excellent properties such as high hardness, high temperature resistance, small thermal expansion coefficient, thermal shock resistance, and slow oxidation.

Various silicon carbide crystals have a similar density of 3.21g/cm3 in general. The Mohs hardness of silicon carbide is 9.5, the Knoop hardness 2670-2815kg/mm. This data is higher than that of corundum and second only to that diamond, cubic boron nitride and boron carbide among abrasives. It’s an abrasive material with a wide range of applications.

Silicon carbide ceramics have high thermal conductivity and thermal shock resistance with small thermal expansion parameters, so silicon carbide ceramics are also a kind of high-quality refractory materials.

Silicon carbide has strong acid resistance but poor alkali resistance. It can remain stable in extreme environments such as high temperature and strong acid, so it has immense application values in petrochemical, aerospace, automotive industry and other fields.

3.ApplicationFields and Prospects of Silicon CarbideCeramics

In view of the many excellent properties of silicon carbide ceramics in chemical, physical, electrical, hydrophilic and other aspects, silicon carbide has been widely used in many fields, and its application scenarios include but are not limited to:

. High-temperature refractory materials:

Silicon carbide can be used as a metallurgical deoxidizer and high-temperature resistance material. It is not only the main material for distillation furnace trays, copper melting furnace linings, etc., but also can be used as heating elements in rockets, aircraft, and automobile engines.

. Wear-resistant machinery field:

Silicon carbide is the most common raw material for the preparation of abrasives and abrasive tools. It can be used as grinding tools, such as grinding wheels, oilstones, grinding heads, sand tiles, and mechanical sealing rings as well as other industrial components.

. New energy storage field:

As an important high-temperature structural ceramic material, silicon carbide has become an important material for absorbing heat on the collector tower of solar power stations.

. Defense and military industry:

Silicon carbide can be used to make high-performance bulletproof armor and has broad application prospects in the military industry.

. Semiconductor material field:

High-purity single-crystal silicon carbide can be used to manufacture semiconductors and silicon carbide fibers.

. Heating and heat exchange field:

In the steel, metallurgy and other industries, silicon carbide is often used to prepare flamethrowers, heat exchangers, radiation tubes, thermocouple protective covers and other devices.

. Composite material field:

Silicon carbide crystals can be combined with metals, other precision ceramics, resin materials, etc. to form composite materials, which not only improves the performance of materials in all aspects, but also meets the needs of the development of various new high-performance structural materials.

4.Summary

With the rapid development of modern national defense, nuclear energy, space technology, automobile industry, marine engineering, etc., the requirements for materials are getting higher and higher. Silicon carbide is widely used in automobiles, mechanical chemicals,, aerospace technology, information electronics and other fields because of its good mechanics and chemical resistance features. It has become an excellent and irreplaceable structural ceramic in many industrial fields.