Provincially certified

laboratory + cutting-edge

R&D center + ISO9001

quality management system

certification+multiple

advanced production lines

Provincially certified

laboratory + cutting-edge

R&D center + ISO9001

quality management system

certification+multiple

advanced production lines

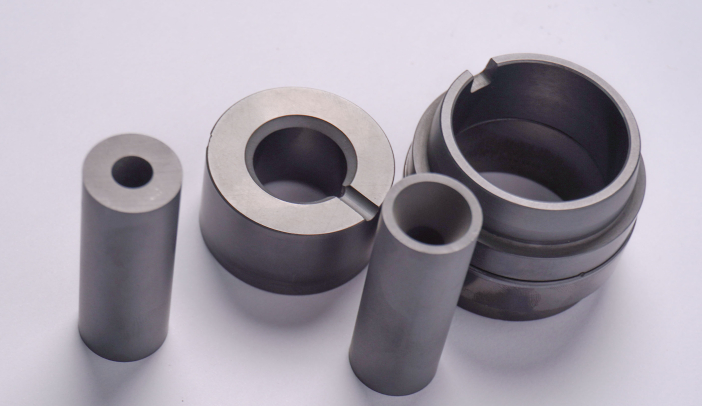

| Name | Boron Carbide | Molecular formula | b4c |

| Attribute |  Download - B4C Download - B4C properties.pdf | Granularity |  Download - Granularity Download - Granularity table.pdf |

| B/C Content |  Download - Download - B&C-ingredient.pdf | Test Report |  Download - B4C Download - B4C test report.pdf |

| ISO9001 |  Download - Download - ISO9001.pdf | Songshan Boron | |

Click the button below for more information and product guides | |||

Contact Us!Get the best price

and information on Boron Carbide

products

As a boron carbide product manufacturer that strictly follows the ISO9001 international quality system standards, we boast the production technologies of ultrafine boron carbide powder of superb purity as well as nano-level boron carbide powder.

At present, we’ve obtained 74 intellectual property rights and comprehensive intellectual property management system certificates. And we’ve successfully dealt with a number of product and production line export cases.

With excellent quality and unremitting innovations, SSPY presents you with easier accesses to superior boron carbide materials.